APARTMENT HOUSE GRADUS RESIDENCE

The new apartment house Gradus Residence in the centre of Dunajská Streda will soon be completed and approved. The entire complex is a mixed-use development comprising residential housing, shops, offices and services.

Lower building

Due to the geology , groundwater and the nature of the structure, the building is based on a foundation slab without dilatation. The base plate is 350 mm to 500 mm thick depending on the load intensity. Depressions with a total thickness of 750 mm are created under the most stressed columns for the sake of overcompression.

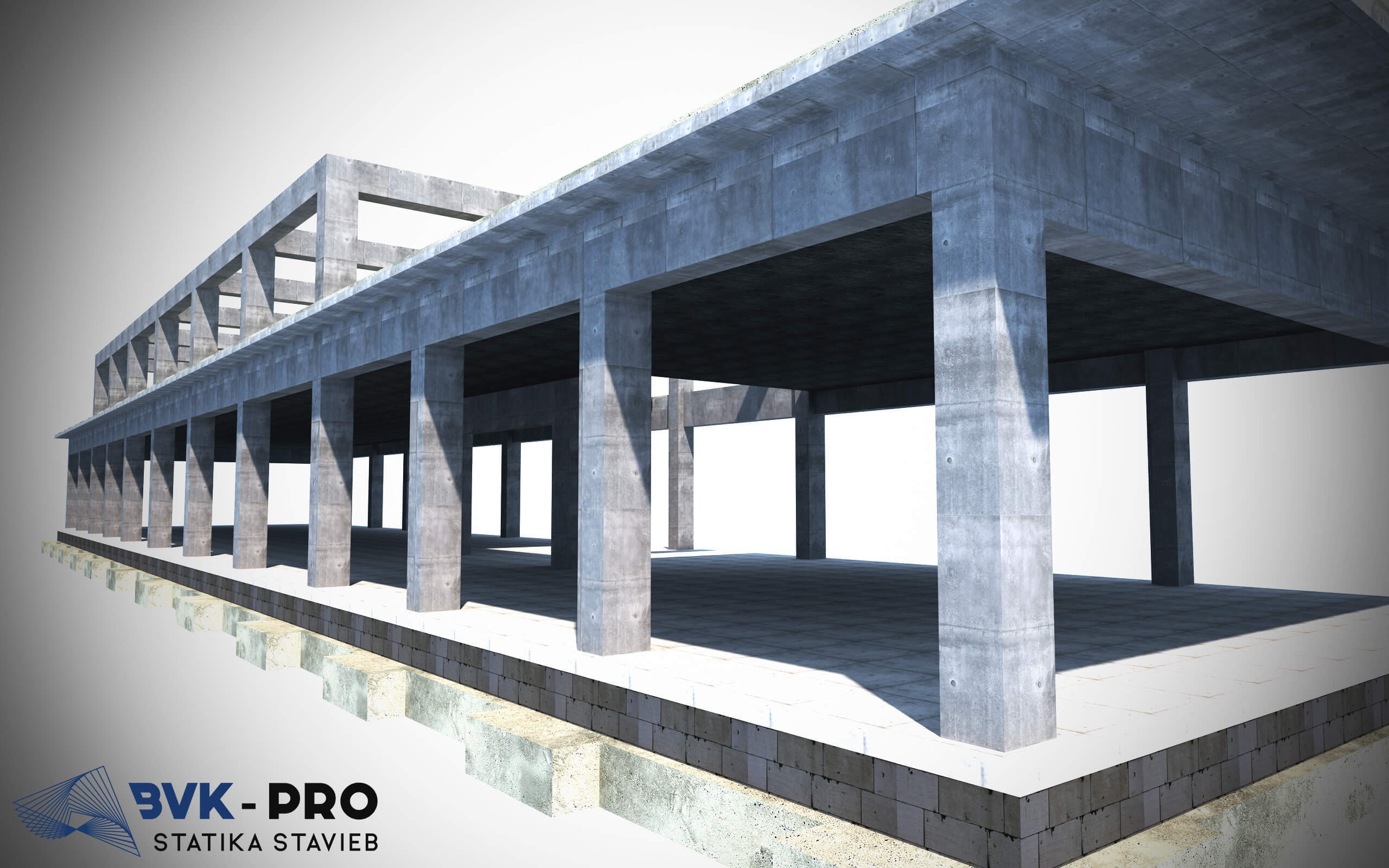

The supporting structure of the building varies in height. In the underground part, the supporting structure consists of a column system with pressure-free floor slabs with a basic modular grid of 5.2 x 6.3 m. In places where there are above-ground objects above the underground garage, the vertical load-bearing system is locally modified to be continuous up to the roof of the above-ground objects, thus ensuring a smooth transfer of loads from the upper structure to the foundations.

A monolithic reinforced concrete wall with a thickness of 300 mm is implemented around the perimeter of the underground garage. The inner walls of the staircase cores are also monolithic reinforced concrete , 150 mm and 250 mm thick.

The columns of the underground garage have a circular cross-section with a diameter of 300 mm. The most stressed circular columns are made of steel profile ROR 298,5 filled with concrete. The other columns are pure reinforced concrete.

The ceiling slab above the 1st floor is designed as a headerless, point-supported, monolithic reinforced concrete slab with a thickness of 250 mm. The ceiling slab is divided into 3 parts by dilatation.

Upper building

The building of the apartment building consists of 5 floors with a plan shape L. On the first floor is a load-bearing system monolithic reinforced concrete column-wall system with reinforced concrete stiffening cores. The stiffening cores run continuously from the foundations to the top floor.

Ceiling slabs above the 1st floor are designed as two-way load-bearing monolithic reinforced concrete slabs, with a thickness of 250 mm. These ceiling slabs are supported by crossbars.

From the second floor up, the load-bearing system is designed as a wall system. The perimeter load-bearing walls are made of ceramic load-bearing blocks with a thickness of 300 mm. Internal load-bearing walls are monolithic reinforced concrete with a thickness of 250 mm, 200 mm and 150 mm respectively.

Ceiling slabs from 2.NP are designed as two-way bearing monolithic reinforced concrete slabs, with a thickness of 200 mm. These ceiling slabs are supported by crossbars.

The balcony and loggia slabs are connected to the ceiling slabs by means of insulating elements to break thermal bridges (isokorb).

The realisation project of the statics was elaborated in BIM by BVK-PRO s.r.o.

3D modelling makes it much easier to coordinate individual transitions and control collisions during reinforcement.

The advancement of BIM is also helped by the fact that many companies already offer their building products processed in 3D, which are then simply inserted into the construction documentation. In this way, thermowells at balcony slabs were modelled and reported to break thermal bridges.

The benefits will also show up when ordering materials, as the reports are accurate and auditable. Many investors do not yet know how to use the benefits of BIM, but they are mentally set in such a way that it will benefit them in the future.

Ing. Csaba Baji

managing director of the company