INTEREST IN TIMBER BUILDINGS GROWS OVER TIME

Interest in timber buildings is growing over time. In order to be a modern up-to-date static office, the Timber Structures division must be an integral part of our program. Engineers specialising in timber construction work in this section of our company. Among our orders you will find sheds, gazebos, family houses, cottages, as well as classic carpentry roofs, truss roofs, hall buildings, and reconstruction.

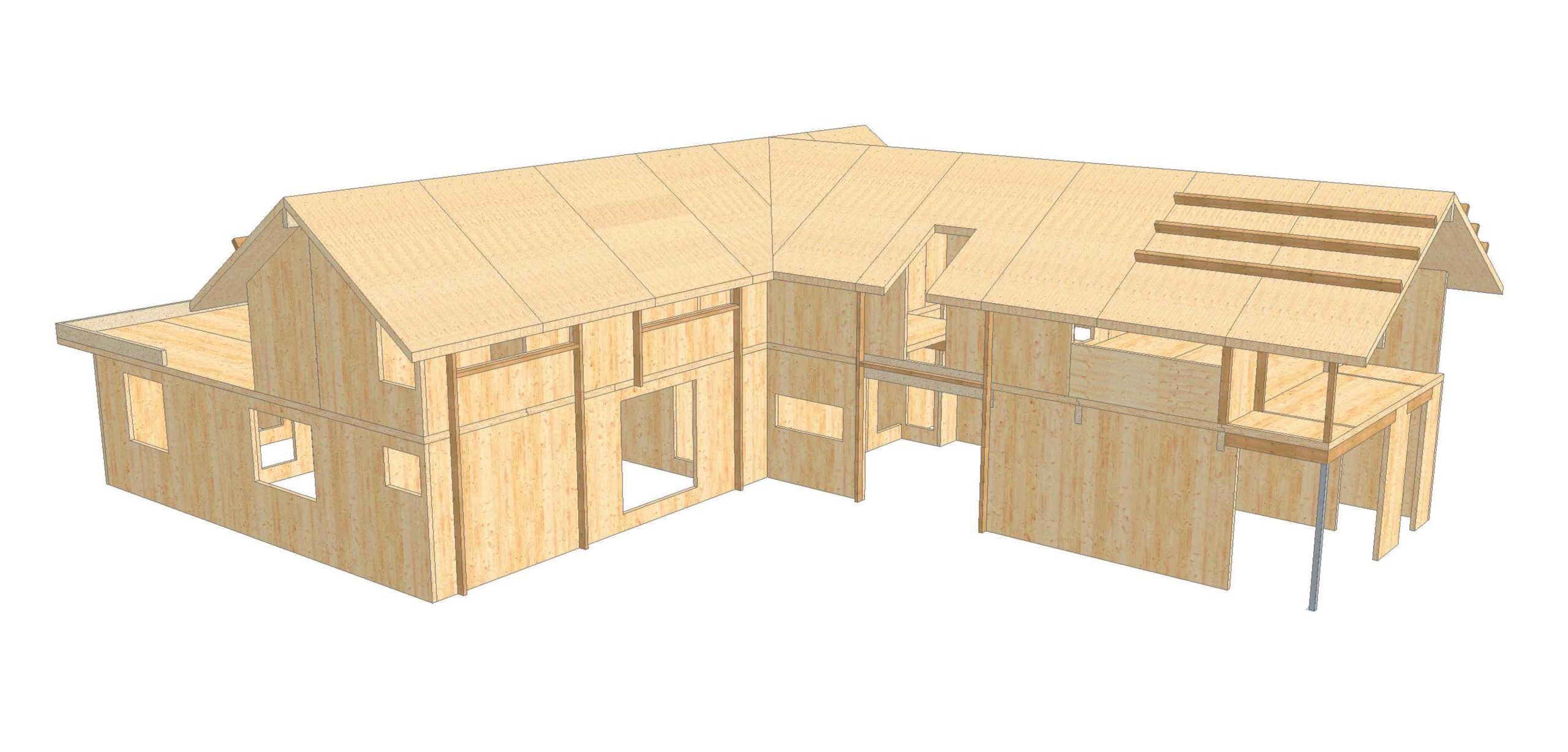

In the course of our practice, we encounter a variety of materials and construction systems. One of the most popular solutions, especially for single-family homes, is cross-laminated timber (CLT) panels. They are panels that are flat elements composed of thin slats glued perpendicularly to each other. They are most commonly designed in thicknesses ranging from 100 mm to 160 mm, depending on visual appearance, degree of fire protection and structural integrity.

For the design and assessment of CLT elements, we use the XLM add-on module of the AxisVM computational software, which uses layered orthotropic 2D finite elements to determine the internal forces and stresses in each layer.

For the family house Močenok, we have secured the implementation project. The final thicknesses and connection types of the CLT wall, ceiling and roof panels were designed after several iterations. The documentation also included drawings of the connections and a list of connecting material.

The second largest group of timber-framed houses is made up of post-and-beam construction, known as two-by-four systems, or frame construction. In these types of structures, the supporting timber posts, upper and lower horizontal members and spacers are made of dried timber. For perimeter walls we use 60/140 mm and 80/140 mm cross-sections, for non-load-bearing walls we use 60/100 mm cross-sections. In order to preserve the spatial rigidity of the house, the ventilation is designed with large OSB boards with a minimum thickness of 15 mm. Therefore, the columns are placed in a 0.625 m grid. Also for these structures, a 3D computational model is built in Axis VM software. Each element is assessed and evaluated separately, but also the complete building as a whole.

Our company is also engaged in the development of production documentation of truss trusses, the essence of which is in the trusses connected by plates with pressed spines. We have already solved production documentation for various types of frame, hall buildings. For these types of structures, we work with high glued beams and can supply complete shop drawings with connections resolved and drawn.

After successful evaluation of the results and assessment of the load-bearing elements, a 3D structural model is created in a specialized program for timber buildings. The SEMA software allows us to accurately model the entire wooden structure with machining. From this structural model, the BIM model can then be exported in various file types with associated element information such as volume, section dimensions, material, view, along with an accurate timber report.

The final project documentation, part of the statics of wooden structures includes drawings of the shape, material lists, technical report with static assessment, in the case of the implementation project we will also supply drawings of connections, drawings of production documentation. Each of our partners receives a 3D model from us in IFC format, which ensures close cooperation with architects, contractors, investors during the design process and during implementation.